What are the components of LED panel light?

LED panel light is a very common kind of lamp and lantern, then it is mainly composed of which parts?

1. LED light source:

Usually use 3528 LED lamp beads, some people also use 3014 and 5050. 3014 and 5050 are low cost, the light effect is slightly worse, and the key is the design of its light-guided dot difficult. 3528 light effect is high dot versatility.

2. Driver power supply:

Currently, there are 2 kinds of LED drive power supply, one is the use of constant current power supply, a mode of high efficiency, PF value as high as 0.95, and cost-effective; the second is the use of constant voltage with constant current power supply, stable performance, but low efficiency, high cost, the general use of this power supply is mainly exported, the other side requires certification requirements, must use the power supply with the safety regulations. The family uses constant current power supply is very safe, because the user finds it difficult to access the power supply, and the lamp itself uses safe low-voltage electricity.

3. Reflective paper:

The back of the light guide plate reflects the remaining light to improve light efficiency, generally RW250.

4. LED panel light aluminum frame:

LED panel light aluminum frame is the main channel for LED heat dissipation, simple and generous appearance, you can use ZY0907, using mold stamping molding costs are low, processing costs are also low; die-casting aluminum frame IP level can be higher, the surface texture is good, the overall beauty, but the initial investment in the mold costs are higher.

5. LED light guide plate:

The side of the LED light through the dot refraction so that the light from the front of the uniform export, light guide plate is the key point of quality control of LED panel lights. The dot design is not good, see the overall light effect is very poor, generally appears in the middle of the bright sides of the dark, or appears in the light at the bright light band, visible local dark area, or appears at different angles of brightness is not consistent. To improve the light guide plate light effect depends mainly on the design of the dot, followed by the quality of the plate, But you don't have to be obsessed with brand name plates, qualified plates between the transmittance are usually very small. General small LED light factories directly buy public light guide plate use, there is no need to re-sample the design, as more manufacturers who use the public plate are usually qualified.

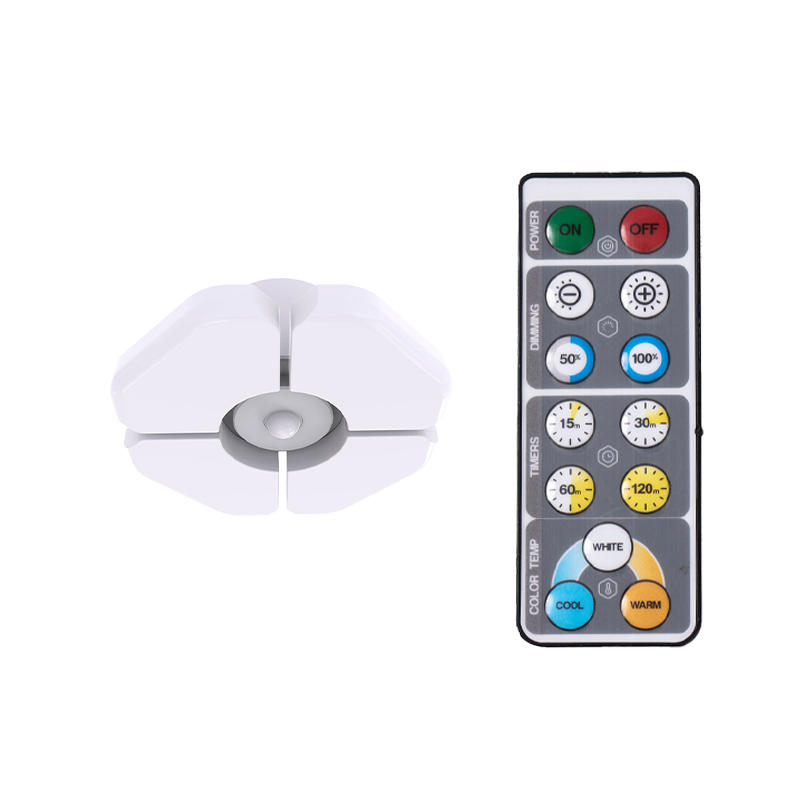

6. Installation hangers:

Suspension wire, mounting brackets, and other accessories used to install fixed.

7. LED diffusion plate:

The light guide plate of the light is uniformly exported but also plays a role in blurring the role of the dot. Diffusion plates generally use acrylic 2.0 sheet or PC material, almost PS material, the acrylic cost is lower and transmittance is slightly higher than the PC high, acrylic brittle aging resistance is weak, and PC is slightly more expensive, but strong aging resistance. The diffusion plate can not be seen after the installation of the dot, and the light transmission rate should be about 90%. Acrylic transmittance at 92%, PC 88%, and PS is about 80%, we can diffuse the board according to the needs of the choice of materials, most manufacturers are currently using acrylic materials.

8. Back cover plate:

The main role is to seal the LED panel light, generally using 1060 aluminum but also can play a little heat dissipation.

英语

英语